Radiation Tolerant Camera Systems

Radiation tolerant cameras are the result of a strong mix of fundamental knowledge, experience in the nuclear environment and customer on-site feedback.

Our products fit with most of the major application and environments in the nuclear sites. You will find a range of products for surveillance and inspection in-air application, underwater application. We also propose fast deployment solutions to allow operators to react quickly on emergency or unexpected situation.

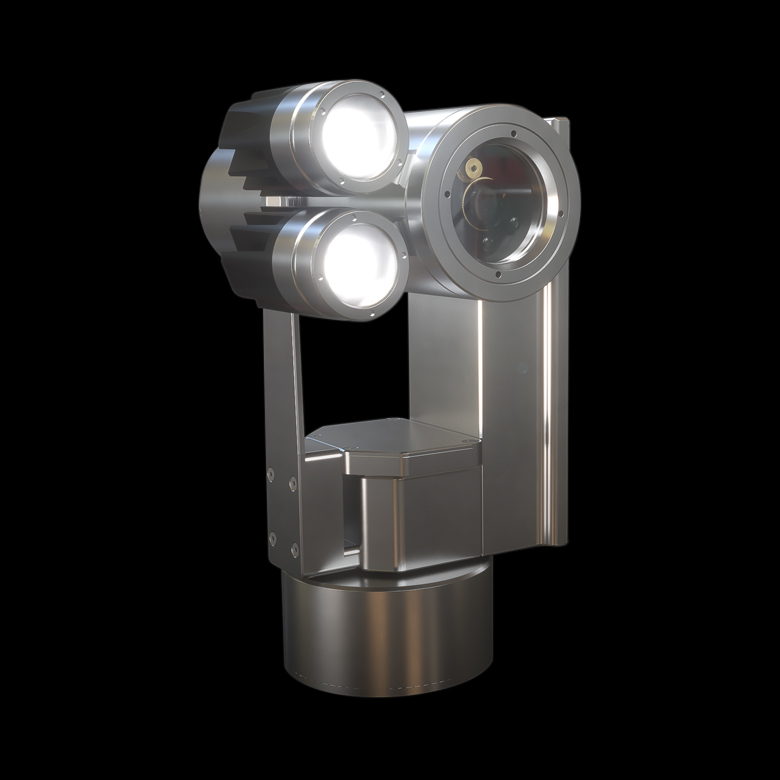

In-air application

Our product range is fully usable for In-air application environments, like storage facility surveillance, Reactor building fire detection, dismantling process controls, one-off remote inspections and more. For PWR, BWR or any kind of reactor, back-end facilities like long term storage areas, reprocessing plants or dismantling operations, you will certainly find the relevant product below.

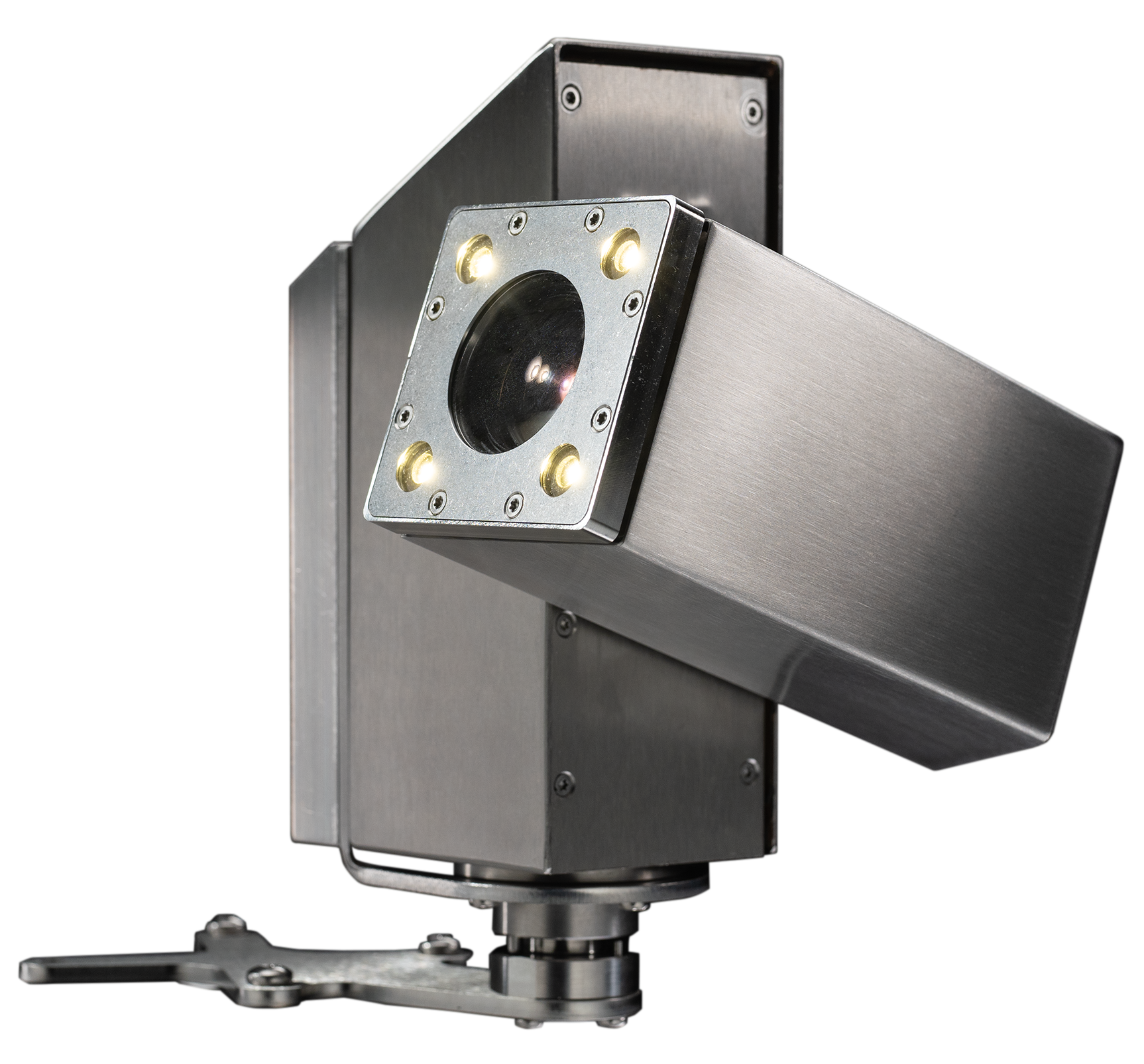

Fast deployment application

Nuclear facilities require radiation tolerant cameras not only for usual surveillance or inspection application, but also in case of unexpected or emergency situations. In that scope, some of our in-air cameras are perfectly fitting with a fast deployment method, that requires a low number of materials and operations to get the vision of the environment.